Mould Making

Mould Making

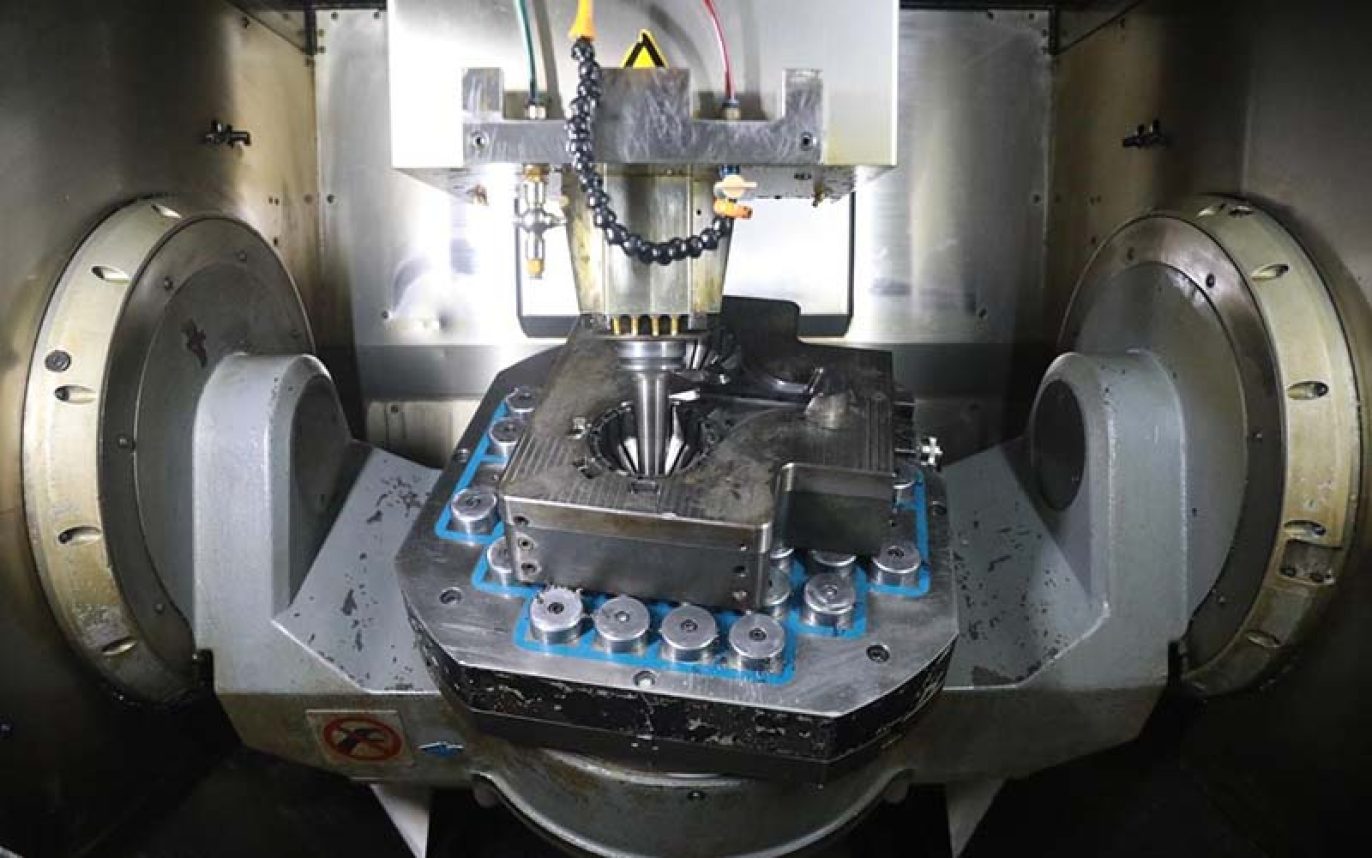

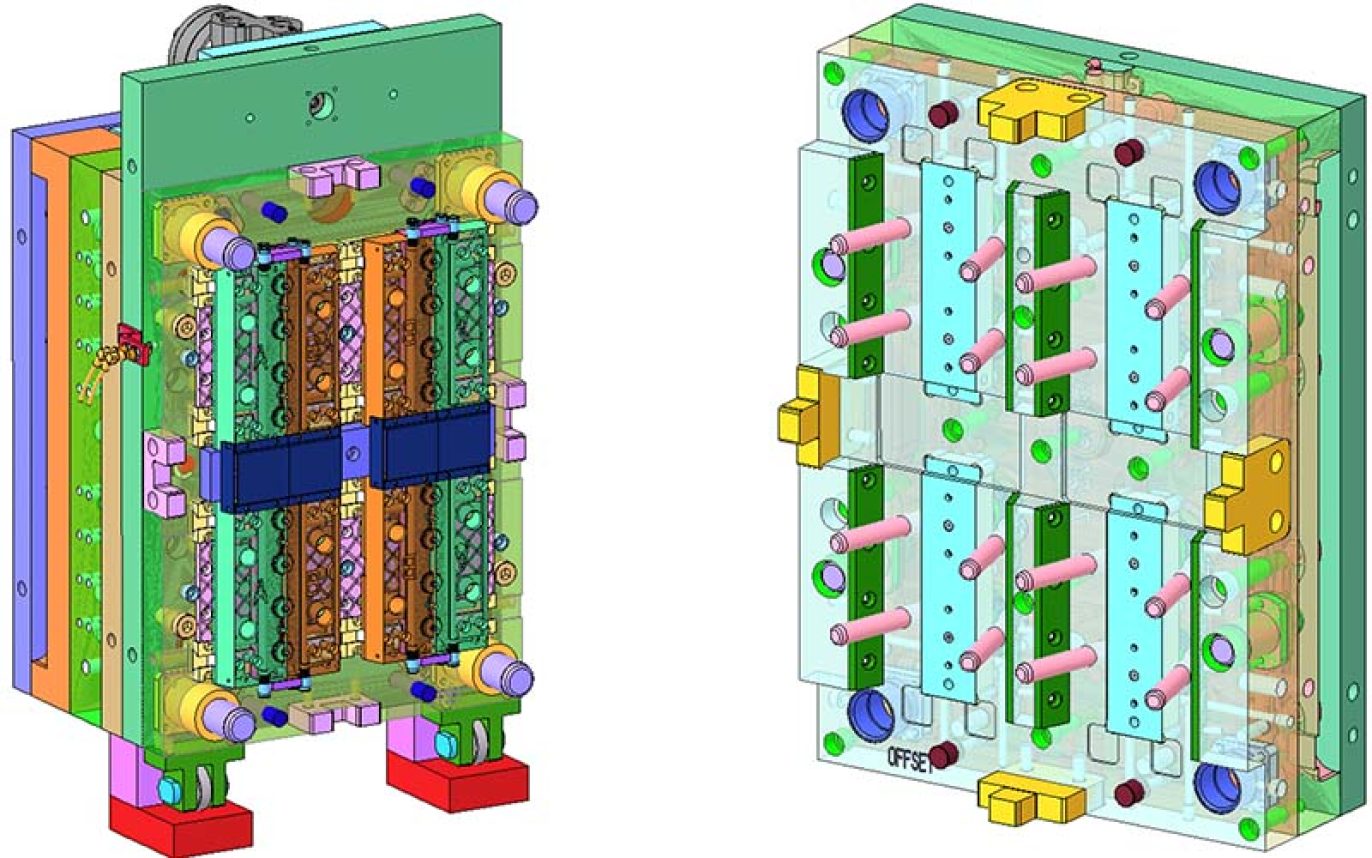

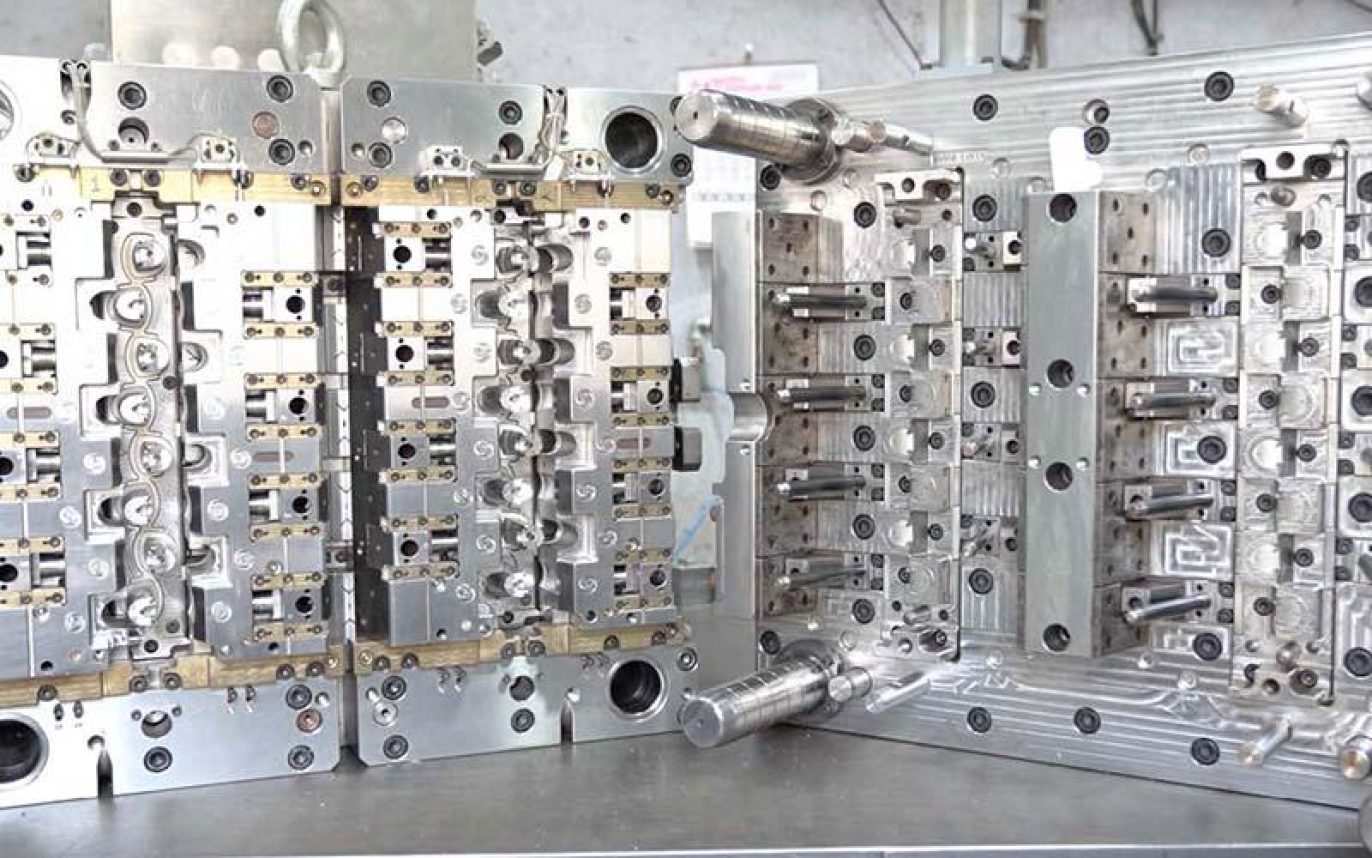

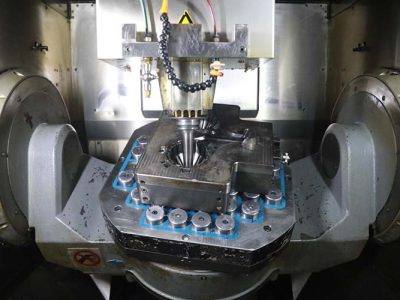

A core competency that makes us a trusted partner for projects encompassing the re-engineering of manufacturing process flows, the creation of tailor-made solutions, or the precision engineering of components and tools. Our commitment to end-to-end development, collaboration, and large-scale production capabilities ensures outstanding results and unparalleled service for all your manufacturing needs, regardless of project size or complexity. Our state of the art toolroom is equipped with over 50CNC’s from world renowned machine tool manufacturers. These include 5-axis simultaneous machining centres , turn mills, EDM’s and so on. We work with cutters as small as 0.2mm, spindle speeds of upto 150K rpm and machine hard parts up to 55HRc. This enables us to produce complex geometries and maintain the level of precision necessary for producing an accurate part.

A core competency that makes us a trusted partner for projects encompassing the re-engineering of manufacturing process flows, the creation of tailor-made solutions, or the precision engineering of components and tools. Our commitment to end-to-end development, collaboration, and large-scale production capabilities ensures outstanding results and unparalleled service for all your manufacturing needs, regardless of project size or complexity. Our state of the art toolroom is equipped with over 50CNC’s from world renowned machine tool manufacturers. These include 5-axis simultaneous machining centres , turn mills, EDM’s and so on. We work with cutters as small as 0.2mm, spindle speeds of upto 150K rpm and machine hard parts up to 55HRc. This enables us to produce complex geometries and maintain the level of precision necessary for producing an accurate part.

Capabilities

High precision

Delivering exceptional accuracy for every project.

Customisable solutions

Crafting tailored solutions to meet your unique needs.

Variety of tools

Ability to develop a diverse range of tools for all engineering thermoplastics for versatile applications.

Complex designs

Expertly navigating intricate design challenges.

High capacity

Upto 600 moulds per year

Quality

Ensuring high precision outcomes with unwavering attention to detail.

Capabilities

Delivering exceptional accuracy for every project.

Crafting tailored solutions to meet your unique needs.

Ability to develop a diverse range of tools for all engineering thermoplastics for versatile applications.

Expertly navigating intricate design challenges.

Upto 600 moulds per year

Ensuring high precision outcomes with unwavering attention to detail.

Product Lifecycle

Product Lifecycle

Mould Making Projects

Outer Dripper

LSR Baby Mask

Micro Centrifuge Tube

Our team is here to help

Our team is here to help

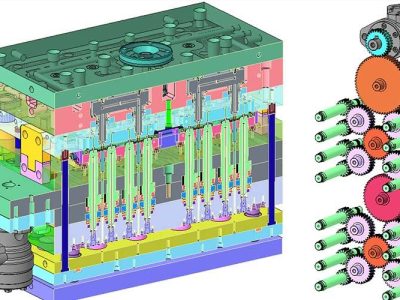

Outer Dripper

Material : PBT

Cavitation : 32 cavity semi Hot runner Direct Gated (HRS built by Mould Masters)

Ejection : Unscrewing

Cycle Time : 35seconds

LSR Baby Mask

Material : LSR

Cavitation : 4 cavity Fully Hot runner Valve Gated (HRS built inhouse)

Cycle Time : 80seconds

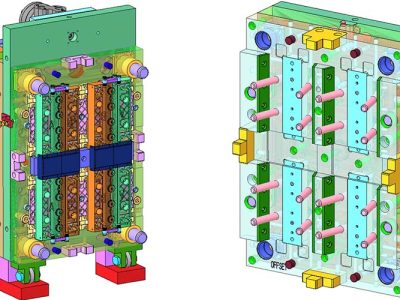

Micro Centrifuge Tube

Material : PP

Cavitation : 48 cavity Fully Hot runner Valve Gated (HRS by Mould Masters)

Cycle Time : 7seconds